WHAT'S THE DIFFERENCE?

CABINET

MATERIALS

There are a variety of materials that a cabinet could be, including T.F.L, R.T.F, Wood Veneer, P.E.T, and H.P.L. Each featuring stunning finishes and textures to make your project stand out.

But what’s the difference? Each material comes with pros and cons, so it is important to know the difference so you can pick the best cabinet for your project.

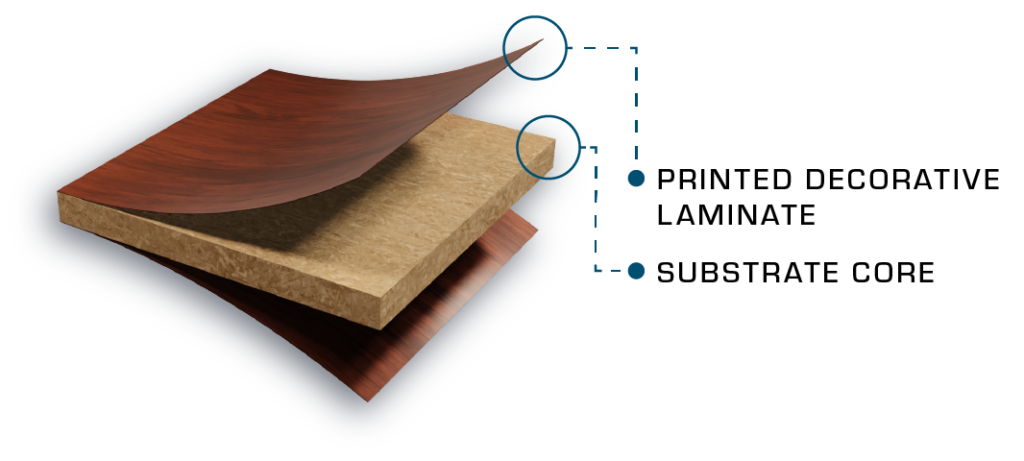

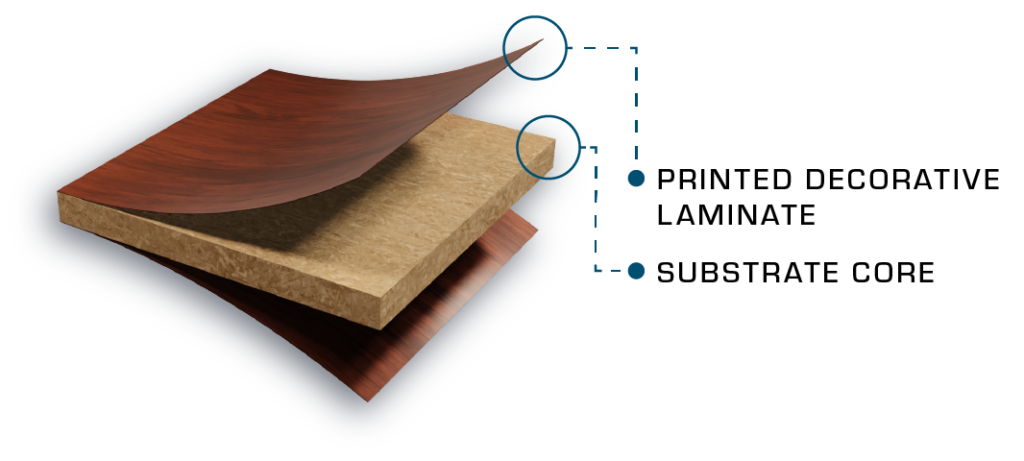

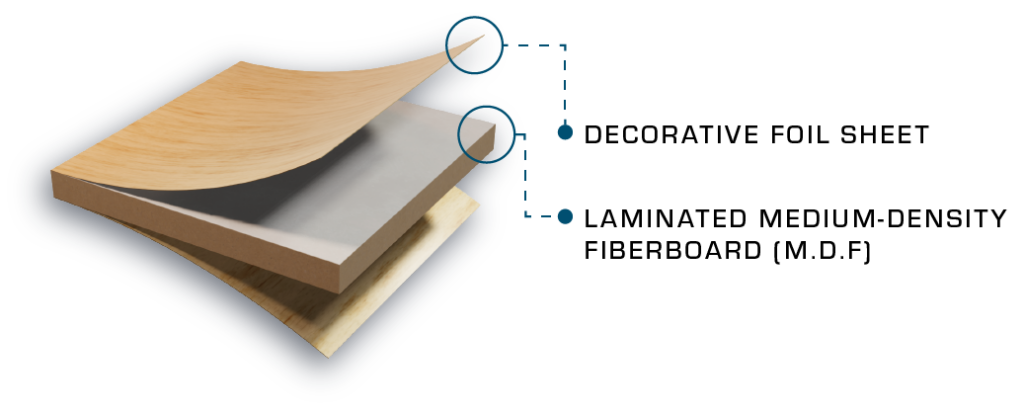

T.F.L

Sleek and stylish, Thermally Fused Laminate (T.F.L) cabinets provide a trendy, minimalist look at a budget friendly price point. T.F.L is widely available and easy to care for with a smooth vinyl surface that will clean like a dream. Check out all of Lanz available T.F.L finished that you wont want to miss.

Thermally Fused Laminate (TFL) panels are produced by fusing a resin-based sheet of decorative paper directly to a particle board core. Pressure and heat activate the resin-based sheet and create a cross-linked bond with the core. This seals the core making it impossible to peel away.

- Lower cost

- Warping resistant

- Permanently bonded to industrial-grade particle board.

- Hardness: 2144 psi.

- Made for vertical application only.

- Less expensive than HPL (high-pressure laminate)

- NOT suitable for countertop surfaces.

- Shorter lifespan

- Susceptible to heat and water damage

T.F.L

Sleek and stylish, Thermally Fused Laminate (T.F.L) cabinets provide a trendy, minimalist look at a budget friendly price point. T.F.L is widely available and easy to care for with a smooth vinyl surface that will clean like a dream. Check out all of Lanz available T.F.L finished that you wont want to miss.

Thermally Fused Laminate (TFL) panels are produced by fusing a resin-based sheet of decorative paper directly to a particle board core. Pressure and heat activate the resin-based sheet and create a cross-linked bond with the core. This seals the core making it impossible to peel away.

- Lower cost

- Warping resistant

- Permanently bonded to industrial-grade particle board.

- Hardness: 2144 psi.

- Made for vertical application only.

- Less expensive than HPL (high-pressure laminate)

- NOT suitable for countertop surfaces.

- Shorter lifespan

- Susceptible to heat and water damage

| Field 1 | Field 2 | Field 3 | |

|---|---|---|---|

| T.F.L | Content 1 | Content 2 | Content 3 |

| R.T.F | Content 1 | Content 2 | Content 3 |

| WOOD VENEER | Content 1 | Content 2 | Content 3 |

| P.E.T | Content 1 | Content 2 | Content 3 |

| H.P.L | Content 1 | Content 2 | Content 3 |

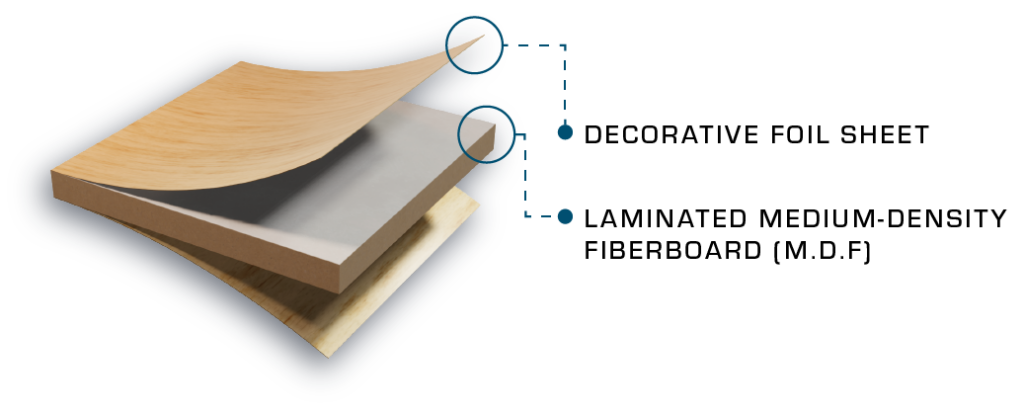

R.T.F

Looking for a cabinet finish option that will look good just about anywhere? Rigid Termofoil (R.T.F) might be for you! R.T.F is a flexible vinyl material vaccuum pressed ovefr its core, so it can mold to fit over ant cabinet style and profile. See all of Lanz easy to clean, moisture resistant R.T.F finishes.

Available for Frameless case construction only.

- Waterproof

- Stain resistant

- Allows for a wide variety of surface finish styles

- Wont warp

- Less expensive that wood

- Only available for Frameless cabinets

- Susceptible to heat damage

| Field 1 | Field 2 | Field 3 | |

|---|---|---|---|

| T.F.L | Content 1 | Content 2 | Content 3 |

| R.T.F | Content 1 | Content 2 | Content 3 |

| WOOD VENEER | Content 1 | Content 2 | Content 3 |

| P.E.T | Content 1 | Content 2 | Content 3 |

| H.P.L | Content 1 | Content 2 | Content 3 |

- Waterproof

- Stain resistant

- Allows for a wide variety of surface finish styles

- Wont warp

- Less expensive that wood

- Only available for Frameless cabinets

- Susceptible to heat damage

R.T.F

R.T.F is a flexible vinyl material vacuum pressed over its core, so it can perfectly fit over any cabinet style and profile. See all of Lanz easy to clean, moisture resistant R.T.F finishes.

Available for Frameless case construction only.

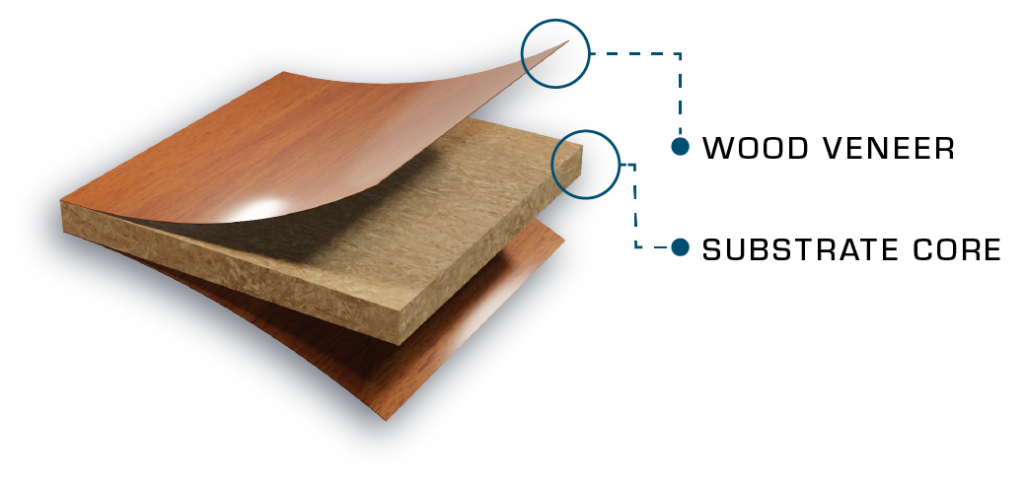

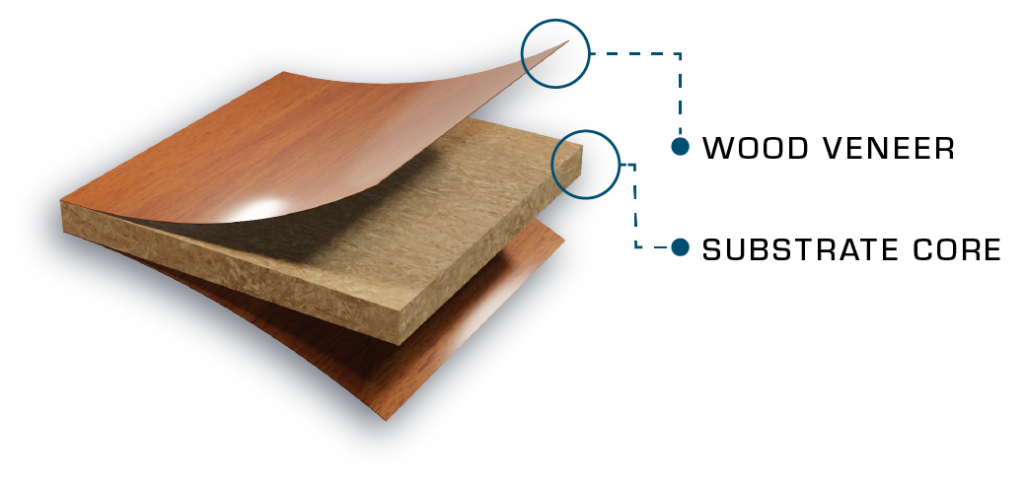

WOOD

VENEER

Lanz offers twelve Value stain/finish options on Alder, Beech, and Oak as well as Premium veneer options in Maple, Cherry, and Walnut. Our natural clear finish coat on all offered species allows the natural color, grain, and character of the wood show through while protecting your cabinets.

- Unique grain from door to door

- Authentic color and grain

- Susceptible to peeling and bubbling when exposed to moisture for too long

- Variable grain patterns make them less uniform

WOOD

VENEER

Lanz offers twelve Value stain/finish options on Alder, Beech, and Oak as well as Premium veneer options in Maple, Cherry, and Walnut. Our natural clear finish coat on all offered species allows the natural color, grain, and character of the wood show through while protecting your cabinets.

- Unique grain from door to door

- Authentic color and grain

- Susceptible to peeling and bubbling when exposed to moisture for too long

- Variable grain patterns make them less uniform

| Field 1 | Field 2 | Field 3 | |

|---|---|---|---|

| T.F.L | Content 1 | Content 2 | Content 3 |

| R.T.F | Content 1 | Content 2 | Content 3 |

| WOOD VENEER | Content 1 | Content 2 | Content 3 |

| P.E.T | Content 1 | Content 2 | Content 3 |

| H.P.L | Content 1 | Content 2 | Content 3 |

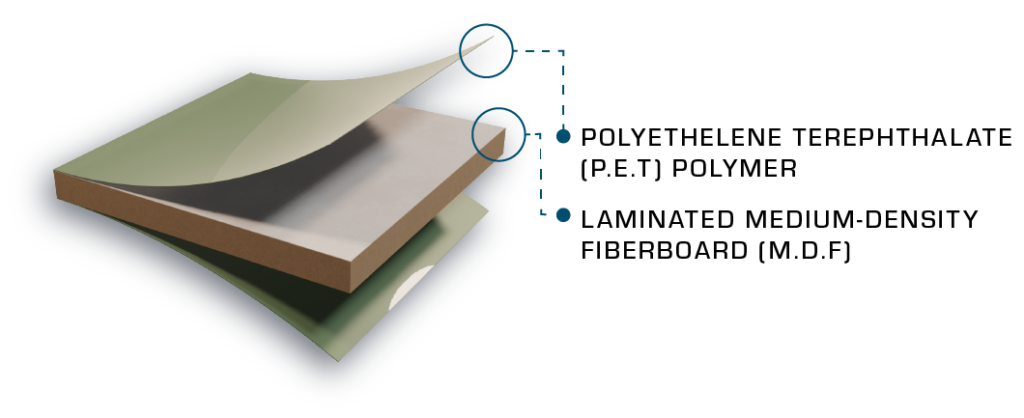

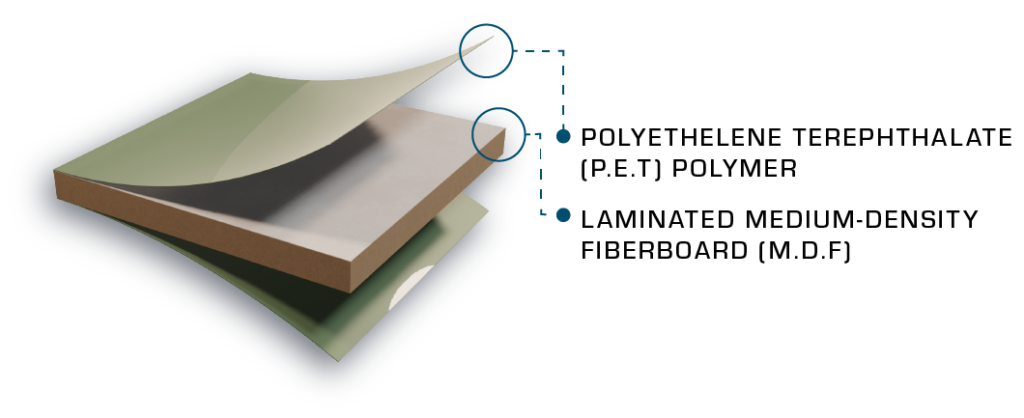

P.E.T

For a busy, hustle and bustle home, Polyethelene Terephthalate (P.E.T) cabinets provide a durable, eco-friendly option that maintains an elegance to make any room shine. Take a look through Lanz UV/Scratch resistant Manhattan P.E.T finished availible in both high gloss and super matte.

- Super Scratch Resistant (SSR) Coating, a hard coat finish for excellent scratch resistance

- Impact and shatter-resistant

- Water-resistant

- Hygienic; does not promote bacterial growth

- Stain and UV resistant

- Won’t crack, peel, flake, or delaminate

- Avoid using rough sponges is not recommended as it can scratch the surface

- Susceptible to UV radiation

- Can begin to warp at high temperatures

P.E.T

For a busy, hustle and bustle home, Polyethelene Terephthalate (P.E.T) cabinets provide a durable, eco-friendly option that maintains an elegance to make any room shine. Take a look through Lanz UV/Scratch resistant Manhattan P.E.T finished available in both high gloss and super matte.

- Super Scratch Resistant (SSR) Coating, a hard coat finish for excellent scratch resistance

- Impact and shatter-resistant

- Water-resistant

- Hygienic; does not promote bacterial growth

- Stain and UV resistant

- Won’t crack, peel, flake, or delaminate

- Avoid using rough sponges is not recommended as it can scratch the surface

- Susceptible to UV radiation

- Can begin to warp at high temperatures

| Field 1 | Field 2 | Field 3 | |

|---|---|---|---|

| T.F.L | Content 1 | Content 2 | Content 3 |

| R.T.F | Content 1 | Content 2 | Content 3 |

| WOOD VENEER | Content 1 | Content 2 | Content 3 |

| P.E.T | Content 1 | Content 2 | Content 3 |

| H.P.L | Content 1 | Content 2 | Content 3 |